Cooling, enery saving, LED, resource

GENENTECH INC.

Genentech Inc. contacted Airius to address temperature regulation problems in their new pharmaceutical warehouse, where the existing HVAC system was not able to reach FDA regulations. Following installation of the Airius system the warehouse passed all FDA validation testing floor to ceiling, wall to wall. It also opened up Billions of Dollars worth of additional inventory space.

KEY POINTS:

- Stratification reduced from 5°C to 1.5°C.

- Billions of Dollars of inventory space reclaimed.

- Facility passed FDA regulations with Airius.

- Used to destratify temperature regulated cooled air facilities.

- System = 50 x Airius Model 25’s.

- Floor Area = 4,600m².

PHARMACEUTICAL WAREHOUSE – DESTRATIFICATION FAN SYSTEMS

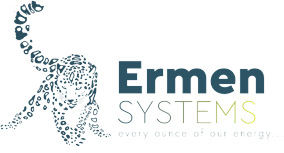

The accompanying thermal images were developed from the temperature controlled warehouse of a major pharmaceuical company. The company’s new 50,000 sq t. warehouse facility in Louisville, KY did not pass the Food and Drug Administraion’s required Temperature Validaion Tests with the originally designed HVAC system.

As can be seen in the ‘Before Airius’ image without Airius fans, the top levels of the pallet racking were exposed to 22.5°C air, too high a temperature for the inventory.

This was a major problem; the facility was due to open and the space was badly needed. The HVAC contractor had tried everything they could think of and had no answers for the problem, short of staring over with a re-designed system. A senior facility engineer suggested the use of Airius for this application. The HVAC Contractor was very sceptical the devices could raise the cold air levels and maintain them. Airius personnel were called in to review the situation and it was determined for this large application that 50 Airius model 25 destratificaion fans would be required and were air freighted at the customer’s request within 2 days.

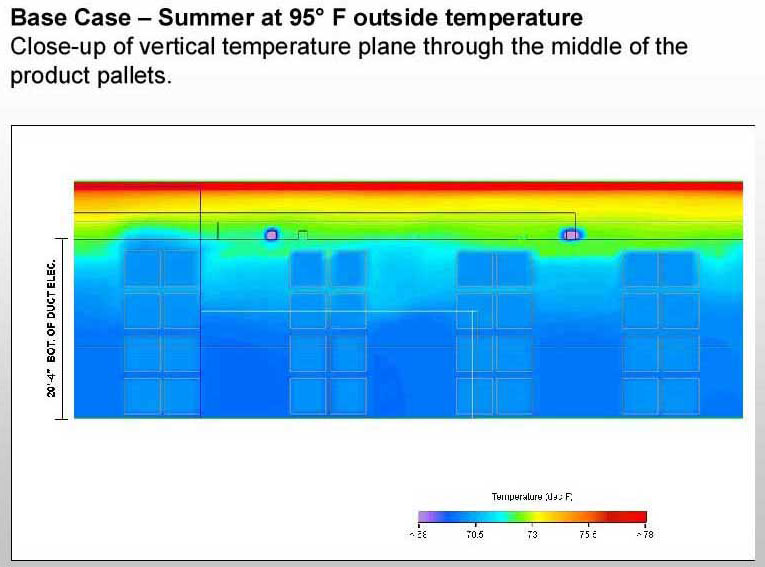

The facility quickly agreed and the installation was a success. In spite of the fact that the destratificaion fans were originally developed to de-straify heated air, and the fact that cold air naturally sinks, it can be seen by comparing the ‘Before Airius’ image to the ‘After Airius’ image that the use of the Airius fans has balanced the level of cooler air in the room to the point where the upper rack levels are no longer in jeopardy – Thermal Equalisation!

The elevation graphic shows a complete equalisation of temperature around the pallet racks supporting literally billions of dollars of inventory from floor to ceiling meeting FDA regulations and approval.