Benefits:

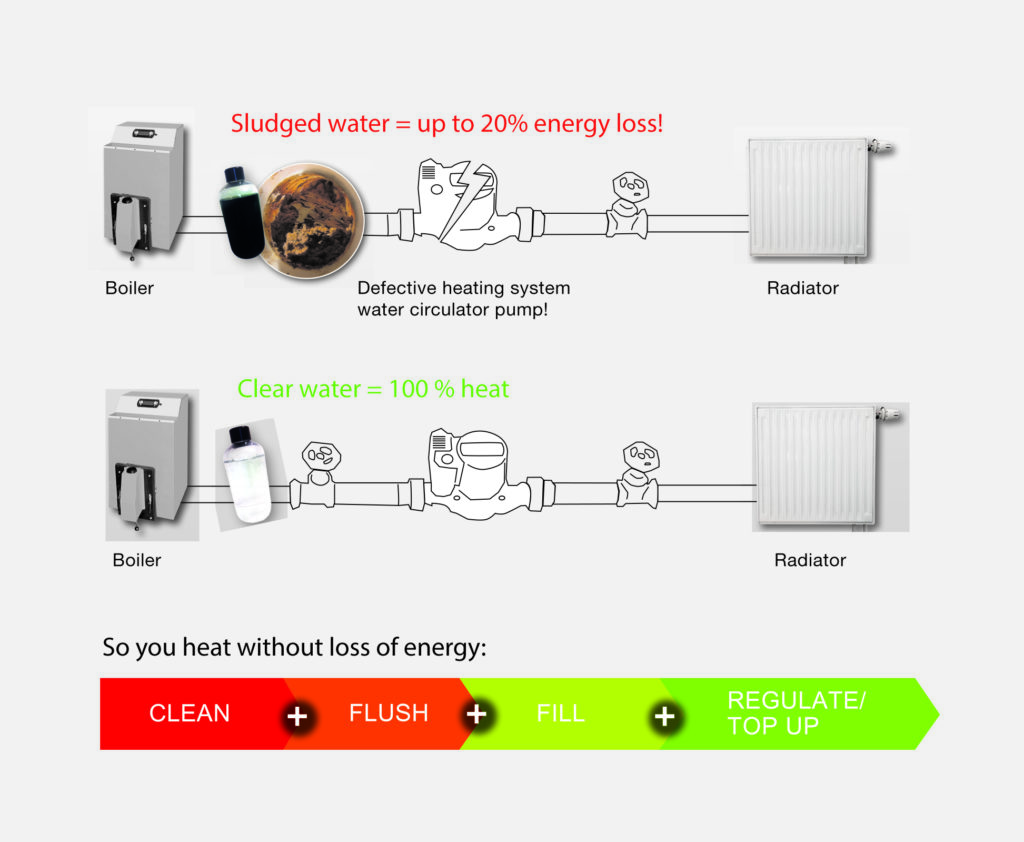

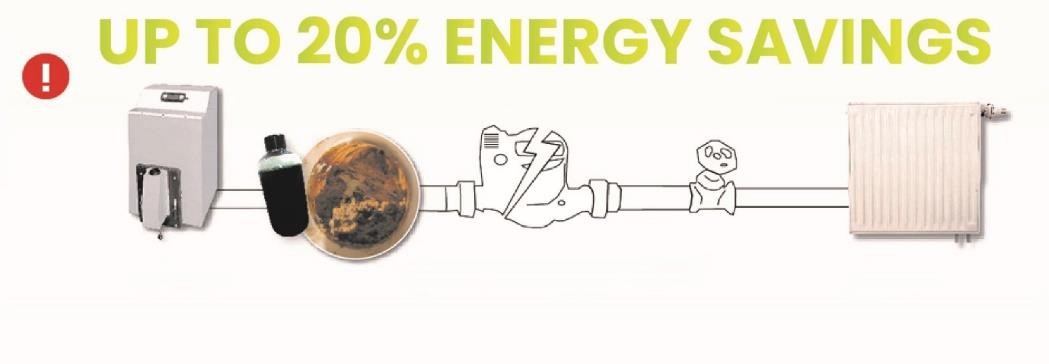

- Reduction in energy costs (Fuel and Electricity)

- Reduction in emissions

- Even thermal transfer and heat distribution

- Less components breaking down (Boiler, Pumps, AHI’s, Pipework, Valves etc.)

- No Chemicals

- Reduction in Maintenance and operating costs

- Reduction in spare parts required

- Reduction in Noise in the system

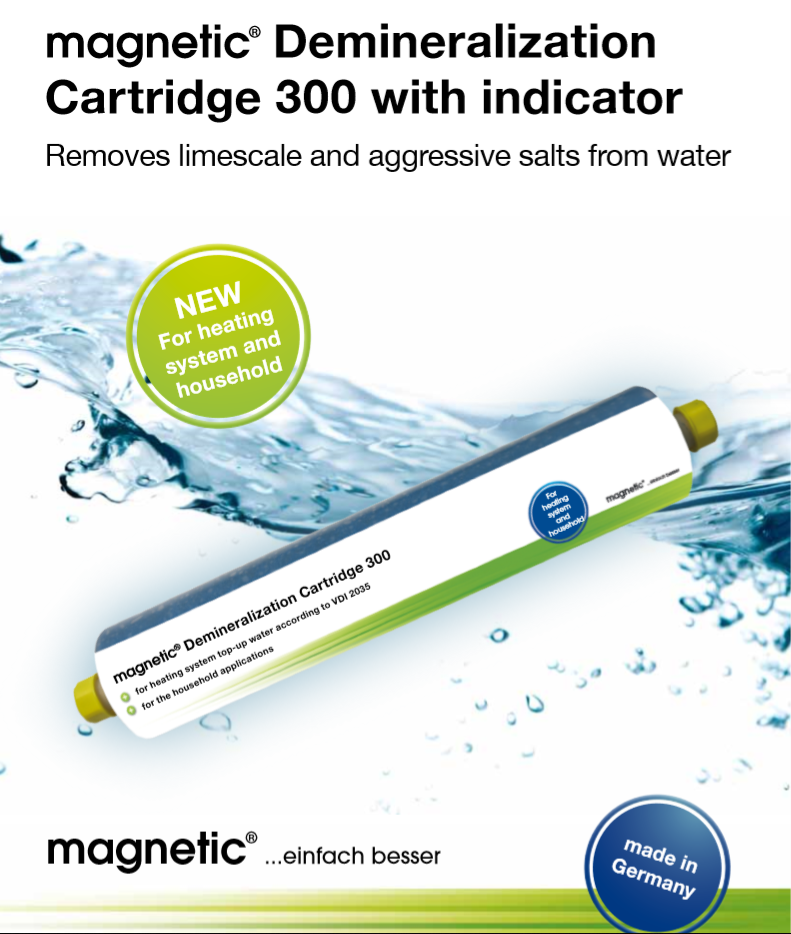

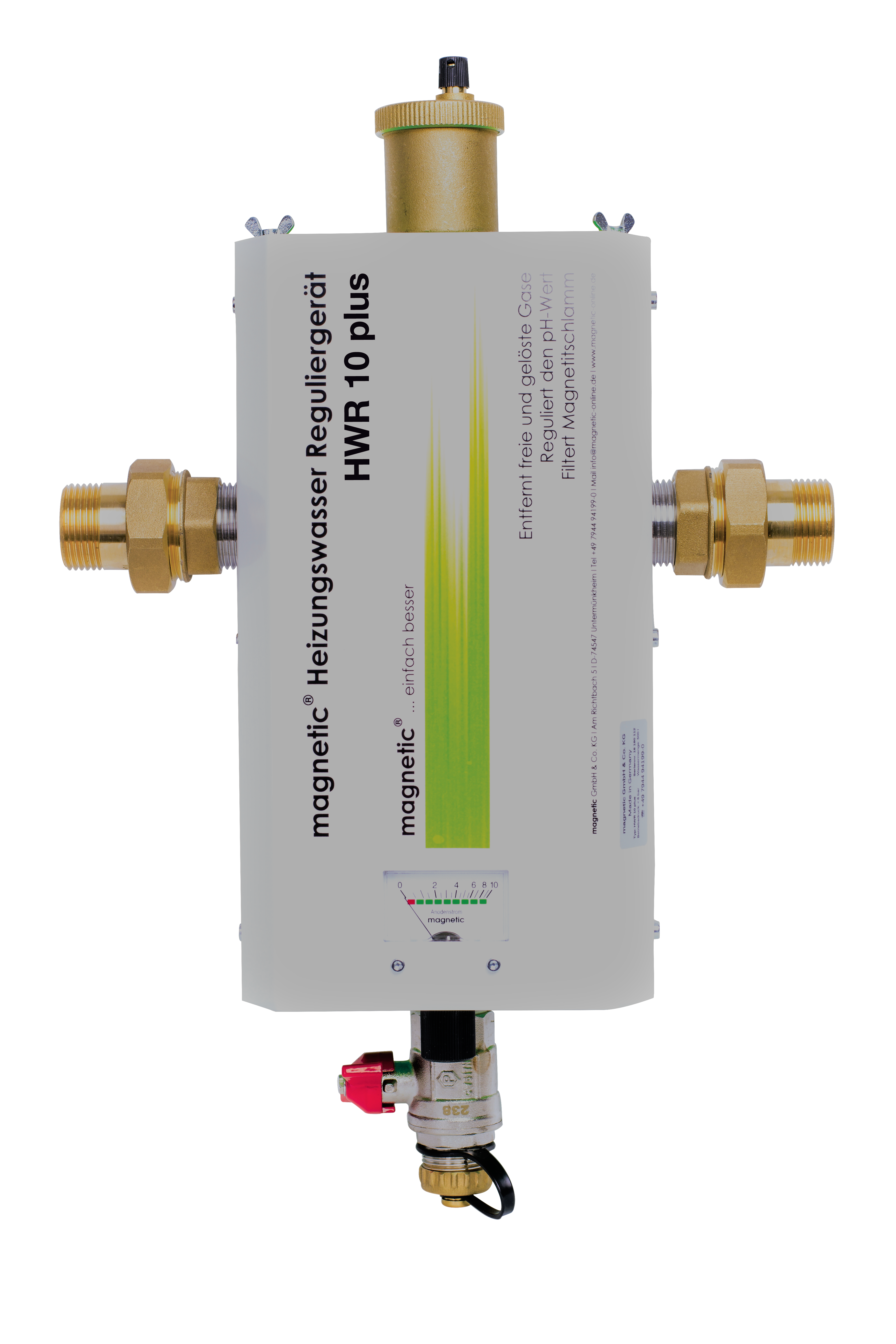

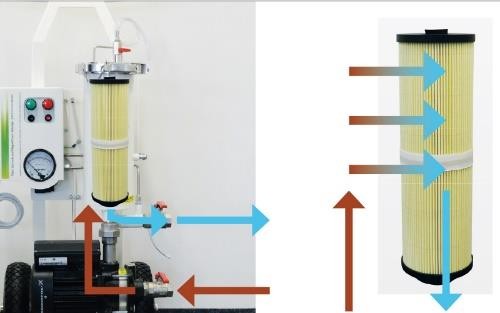

Components of Demineralisation:

Outlined below is a brief description of the various tools available to carry out and maintain the Demineralisation process. There are links to more detailed information and brochures for each component.

The Implementation steps are also listed in sequence.