Current Application:

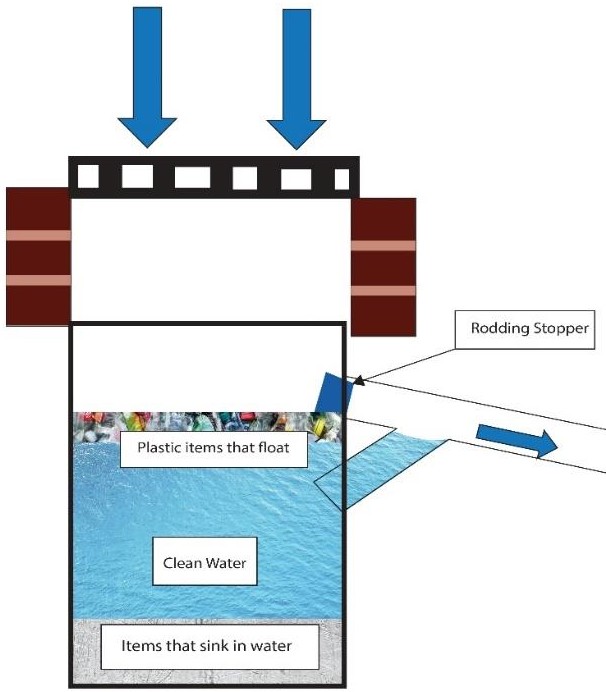

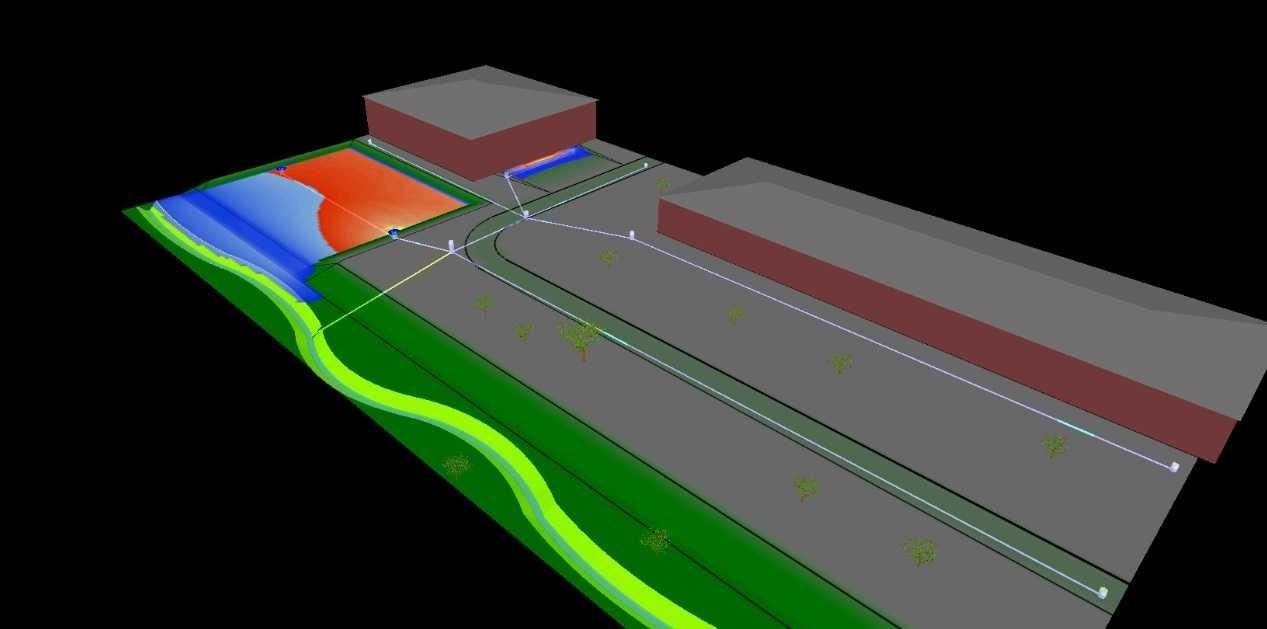

We have a plastic site that is signed up to operation clean sweep, global initiative. We have made them a filter for gully pots and are now spill modelling and surveying the drainage. What we found was that every gully pot on the site was not operational, the rodding bung was not fitted. Simple issue for plastic, cigarettes, oil going into the rivers and sea. It is imperative a clear understanding of how on-site drains work, is established.

We can impact plastic pollution in two easy steps.

- Fix existing drainage on site

- Install Correct Firewater Containment/Pollution control system.

The challenge here is plastic pellets. Sites have found product at the discharge outlet a mile away and then 15 miles away in the Rivers and Streams What we have discovered is that sites do not understand drainage. My work therefore went from product to education as a consultant. The client has now commissioned us for survey and to put the drainage right as well as manufacture filters in high risk areas. The site had spent a fortune on spill products and consultancy, and I think the approach of understanding source-pathway- receptor is best approach. The pathway is now working as intended. They now are looking to fit Toggleblok so that is a major spill or fire occurs they can shut down the pathway. ZERO plastic pollution. Key Requirements:

- Client Education

- Correct Drainage Issues

- Design Drain Filters and Install

- Spill Mapping

- Understanding Source-Pathway-Receptor

- Install Toggleblok to ensure containment and Zero Plastic Pollution.

The site must have:

- Accurate drainage plans

- Try to eliminate pollution risk, move product from drains. We know this isn’t always possible

- Understand the source of pollution. Does it separate in water, if it does the drainage can be made to work to eliminate pollution risk. If it is a miscible substance it must not enter a drain, if it does a site needs Toggleblok to stop flow allowing for product removal. Valves are best fitted near the risk to reduce volume and potential mixing with rainwater.

- Receptor, ideally a site should know where pollution could end up so if the worst happens, they can act responsibly.

Plastic pollution is now global news and I think brands will find it awkward if they are called out as a polluter.