resource

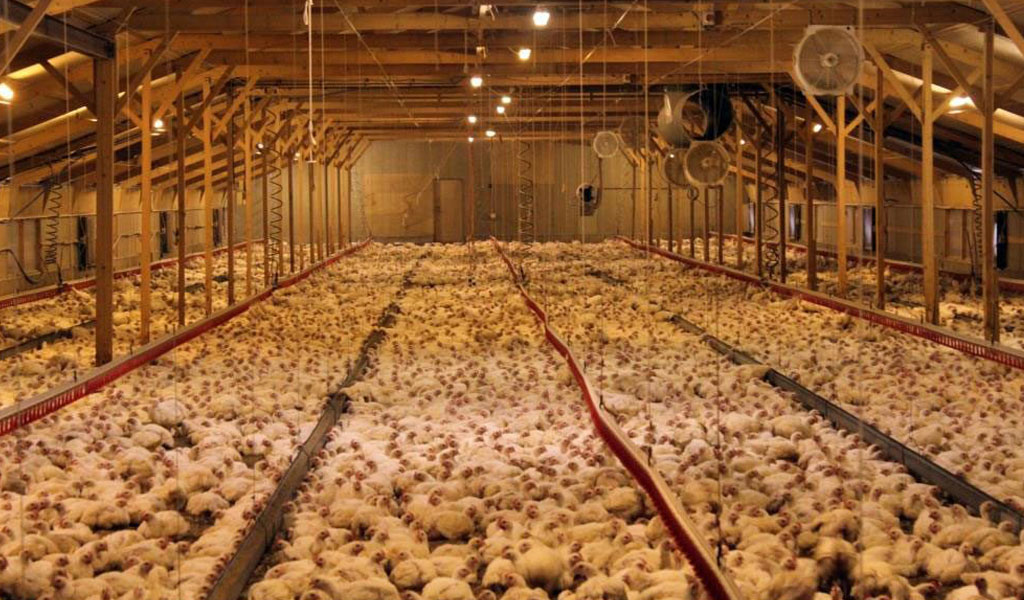

POULTRY SHEDS

In the case of poultry rearing sheds, particularly those using gas heating, thermal stratification has a very costly impact. The roof is heated initially, followed by the main cavity of the building before finally reaching the floor. As the birds are grown at floor level most of this heat is wasted, heating every other part of the building, before finally heating the area where the birds reside.

KEY POINTS:

- 20% – 50% heating cost savings

- Air purification feature

- Improves bird well-being

- Simple installation

- 8 tonne of C0₂ savings (approx.)

- Mitigates bio-security concerns

- £384 – Approx annual running costs

- Creates a healthier environment

- Ideal for new and retrofit builds

- Reduces wear & tear on HVAC system

WHY DESTRATIFICATION?

In the case of poultry rearing sheds, particularly those using gas heating, thermal stratification has a very costly impact.

As hot air rises the roof accumulates the heat first, followed by the main cavity of the building before finally reaching the floor.

As the birds are grown at floor level most this heat is wasted, heating the higher levels of the building before finally reaching the area where the birds reside.

POULTRY SHEDS – DESTRATIFICATION FAN SYSTEMS

Through the implementation of a destratification system, hot air in the roof is recirculated down to the floor continuously. In this manner, the cleaner, hotter air in the roof is recovered and redistributed to where it is needed at floor level.

This leads to a significant reduction in gas consumption, the greatest non feed expense in rearing birds.

WHAT AIRIUS PROVIDED

Operational & Environmental Savings

A significant reduction in running costs was recorded for the gas consumption, ranging from 20% – 50% savings. An additional benefit is the savings in Carbon Emissions. It is estimated that implementing the Airius solution in poultry shed saves up to 21.8 tonne of C0₂ annually.

Running Cost

The Airius system is designed to offer significant savings, with negligible running costs. The units operate at 15 Watts each, the annual running costs for a shed with 10 units is less £384.43 annually.

MAINTENANCE FREE & ROBUST SOLUTION

The unit’s motor housings are sealed preventing dust and other contaminants from damaging the inner components, ensuring their ability to operate smoothly in the harshest conditions of the Poultry shed environment. This unit is also specifically designed to mitigate any bio-security concerns and meet the highest industry standards as defined through consultation with leading industry vets.

SIMPLE INSTALLATION

The solution is perfect as both a retrofit option, as well as for new sheds and can be installed by any local electrician with minimal disruption.