Global sales have now exceeded 150,000 units.

Immediately! The moment the units are switched on, the efficiency of the building and HVAC system will start to improve, reaching their full potential once equalisation is achieved (within 48 hours depending on the size of the building).

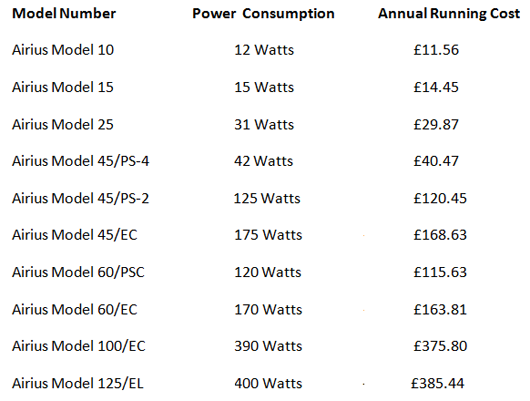

Airius units are extremely efficient drawing a tiny electrical load. Using less than 5% of the power of some of the competing box type destratification fans. The figures below are the annual running costs based on the units running 24 hours a day 365 days a year, at an electrical cost of 11 pence per kWh.

Savings range hugely from building to building with average savings of 30 – 50%. With over 100,000 units sold we have had reported savings ranging from 20% to 76%. This is down to a number of factors, such as:

Ceiling Height:

The higher the ceiling the higher the level of savings for your property. This is due to a greater percentage of the area being overheated, leading to higher levels of stratification and in turn heat loss. The Airius units eliminate this stratification, minimising the buildings heat loss.

Insulation:

A well-insulated building will capture the maximum amount of heat at roof level leading to high levels of stratification. Airius units then equalise the temperature achieving standard 30 – 40% savings (depending on other factors).

The lower the level of insulation the higher the saving. This is due to a vastly increased level of heat loss, mainly escaping through the roof. The Airius units capture and recirculate the heat before it has the opportunity to escape.

Achieving Temperature:

If the thermostat set point is being achieved at ground level then the saving will be higher. If not then the Airius units will still reduce a building’s heating requirement.

The difference being that if the thermostat set point is not being achieved then the first part of the heat load reduction will be used to reach the thermostat set point before savings can be achieved.

Process heat/ Ambient heat

The higher the level of process heat, the higher the level of saving. Process heat is a term used for any heat produced by an internal process other than from the HVAC system. This process heat can be produced by anything from factory machinery, motors and ovens, to computer equipment, lighting and even body heat.

Ambient heat from sun light, even in winter coming through skylights, heated steel roof panels and windows will also be utilised.

This process/ambient heat rises up into the roof space and will be captured and recirculated further reducing the demand on the heating system.

The way Airius units work to reduce cooling costs is slightly different to heating. Typically in cooled spaces those people near the cooling outlet are too cold and those no more than a few metres away are too hot. People by windows can also get too hot due to solar gain and so on.

The Airius units help by equalising the temperature making sure that everyone benefits from the cooling as quickly as possible. It also helps the cool air reach thermostat set points quicker.

The Airius system also ensures that every bit of air in the building is moving very slowly. This gentle air movement across the skin creates a lower perceived temperature (evaporative cooling), allowing you to turn your thermostat up by between 2 and 4°C.

This along with the equalised temperature has proven to reduce cooling costs by anything from 20% up to 100%. This is due to the low cooling requirement in the UK. You only need to reduce the cooling load slightly to make huge savings.

Cooling Testimonials:

Bowlplex PLC

“We are very impressed with the results Airius fans have achieved in our ten pin bowling centre at Nantgarw in South Wales. The atmosphere inside has been greatly improved reducing staff & customer comfort complaints by 90%.

They have also allowed us to increase our thermostats from 19°c to 23.5°c resulting in a saving of over 70% on our cooling costs! The Airius system has far exceeded our expectations & will be standard equipment for all our 18 bowling centres in the UK.”

Ben Carne – Energy Manager

Tiso Ltd

“The Airius system was installed during the summer whilst the AC system was closed down for servicing and we were happy to find the environment now comfortable without the AC running. This has now led to the entire AC system being decommissioned with a considerable reduction in electricity consumption. We now consider destratification systems as a key part of our refits”

Iain Calder – Property Director

In most instances the optimum mounting height is 20 – 100cm (depending on the model) below the ceiling, but the units can be bolted directly to the ceiling without impeding the airflow.

The only reason we don’t recommend this as a standard is because over time dust marks will start to show on the ceiling.

If the building has little to no insulation such as a single skin tin roof, it is best to hang the unit 120 – 300 cm (depending on the model) below the ceiling. This stops the units drawing cold air off the surface. The more powerful the unit, the further away it should be hung.

Airius is the world leader in destratification technology. A combination of innovative and continual R&D along with the use of the highest quality materials and motors enables Airius fans to achieve great results whilst requiring very minimal power usage across the range.

The unique way in which air is moved using Airius patented stator vane technology, creates up to 15 times more air to be circulated in the space than is exhausted through the fan itself, as a result of entrainment. This huge volume of slow air circulation achieves the most efficient and effective method of destratification available.

For example the Airius model 45/PS-4 uses only 42 Watts and equalises the temperature in buildings with ceiling heights of up to 13 metres.

Other destratification fans available on the market which claim they will equalise temperatures at the same height use as high as 870 Watts. This is over 20 times as much power, which in turn leads to more noise, more turbulent air and a much shorter life span.

Airius units effectively equalise the temperature with an airflow rate as low as 15% of that of other destratification fans.

This is achieved by the unique patented stator vein technology within each Airius unit, producing a tight column of air which encourages huge levels of air entrainment. The volume of air circulated through entrainment is up to 15 times higher than the volume produced by the unit.

No, we do not charge to carry out onsite surveys.

However this is on the condition that we have received and gone through all the relevant project information via phone or email to ensure we meet your goals. Based upon this information, we will happily carry out a full site survey free of charge.

At the request of a number of customers Airius launched an in-house Installation Team late 2015. As well as a fully qualified Installation Manager we took on three other team members including an Apprentice under a three year scheme.

The Installations Manager, Lee Charlton, has extensive experience and offers a really professional service. Airius has invested heavily in equipment including a 10m Scissor Lift, scaffold tower and two trailers. Lee can conduct a full site survey if needed and then carries out the installation of our units to ensure optimum performance.

Airius are dedicated to installing our Destratification fans to the highest possible standards. We ensure all installations are carried out in accordance to BS 7671 (currently 17 edition amendment 3).

Installation costs are normally more competitive than local competing companies due to owning our own range of access equipment.

Airius Europe Ltd are fully NICEIC accredited under there Approved contractor scheme. In using our in house team you can ensure that your Destratification project works to its full potential.

In many cases customers like to use a local or preferred contractor. When this is the case we give full technical support where required.

If a units fails outside of the 5 year warranty period, you may return the unit to Airius Europe Ltd to be refurbished at 60% of the current retail price (refurbished units will be mechanically as good as new and will come with a full 5 year warranty), or simply purchase a replacement unit at 80% of the current retail price.

Stratification typically occurs at a rate of 0.5 –2ºC per metre and temperature differentials of up to 10°C are common over a height of 10 metres. In extreme cases, temperature differentials of 10°C have been found over a height of 3 metres.

The degree of stratification depends on a number of factors such as the building materials, level of insulation, activity in the building, heating/cooling set points and the outside temperature.

It is wrong to assume that if the level of stratification is at the lower end of the scale there is not much to be gained. This can be down to a number of reasons, such as:

- The heating is off

- Outside temperature is at or above room temperature

- Insulation levels are so low, heat escapes before it can build up. Our most successful case studies have been from buildings like this (View Lush & Impress case studies).

In normal conditions the Airius range should equalise the temperature to within a 2°C band floor to ceiling.

Yes, however we recommend that the units be left to run 24/7 throughout the heating season.

This is because as soon as the system is turned off, the warm air is allowed to rise again and by letting the temperature at ceiling level increase by any amount increases your buildings heat loss significantly.

Also, as the Airius units send the air down to ground level, which then blankets across the floor at 4 to 6 inches high. The floor gradually starts to heat up and becomes a thermal battery. The heat stored in the floor is then slowly released whenever the heating is not running.

This has been a tough message to get across as people tend not to want to leave an electric motor running, especially not overnight if the building is not occupied.

To prove the benefits we conducted a study at a pharmaceutical storage facility (Chemilines), where they were strongly against leaving the units running overnight. The company was losing between 10 and 12°C during a typical winter’s night when the heating and Airius units were switched off.

As a result, the company had to turn on their heating for 2.5 to 3 hours before the staff arrived to ensure the temperature was at a comfortable level.

The company then conducted the same test with the Airius units running. With their heating system turning off at the same time they found that instead of losing 10 to 12°C, they were only losing 2.5 to 3°C! This reduced their morning pre heat time from 2.5 to 3 hours to 30 to 45 minutes. The reduced heat up time alone amounted to a 20% saving.

We only recommend turning the units off if your building is going to be unheated for a period of more than 24 hours.

When a large roller shutter door is opened large atmospheric losses will occur. Airius units simply stop the outside air from penetrating into the building as far, and more importantly once the door is closed the building recovers at a much faster rate.

A perfect example of this would be aircraft hangers where the entire wall opens up in the building. Even with this aircraft hangars achieve some of the highest levels of savings, ranging from 35% right up to 60%, with little to no process heat to help.

In ambient or warm product storage areas there are often problems with stratification and hot and cold spots. This leads to large areas of the store not being suitable for use, products having to be quickly relocated or results in high wastage.

Airius units work the same way here that they would in any building. They keep a consistent equal temperature throughout the space from floor to ceiling. This ensures that every part of the space can be used to store even the most temperature sensitive products at the lowest possible cost.

Cold stores have the same problem in reverse. In order to get the higher levels to the required temperature you are forced to overcool the ground level, which is a huge waste of energy. Airius units will simply and efficiently equalise the temperature ensuring that the building and the cooling system are working to the best of their ability.

It is a common misconception that when an area is being heated using any form of radiant heating system, there is no benefit using destratification fans.

This is simply not true. It is true that the heat felt at ground level is not from the air around you being warm, and the warmth you are feeling does not cause stratification.

The stratification occurs up at the height of the radiant heaters themselves. The radiant tubes can run at anything from 700 – 2200 ᵒC, this then superheats the air around the tubes leading to stratification.

When using Airius units with radiant heating systems the positioning is much more critical. The fan units should be positioned at a maximum of 80cm higher and 100 – 150cm to the side of each radiant tube. This ensures that all heat is captured and the buildings heat loss is kept to a minimum.

Global sales have now exceeded 150,000 units.

In independent tests RGF PHI Cell technology was shown to have a 99.9% inactivation rate on surface and 99.5% inactivation rate on aerosol forms of the SARS-CoV-2 (COVID19) virus.

Testing commenced in March carried out in a 36m3 (1,280ft3) testing chamber using the SARS-CoV-2 virus, not a surrogate or similar virus. Results show the virus is killed on contact with the PHI’s cleaning agents, effectively neutralising the virus within the chamber within a matter of minutes.

It is important to note that no medical claims are made.

There are two types of air purifiers available for home use, which use two main kinds of purification processes. These are:

- Passive type air purifiers, which are the standard HEPA filters, where the air is drawn into the machine and passed through a filter to remove contaminants, before clean air is released on the other side.

- Active type air purifiers, that send cleaning agents out into the space to clean the air, and create an ambient atmosphere.

Photohydroionisation (PHI) is an advanced oxidation technology developed to minimize and neutralize indoor air pollutants such as bacteria, viruses, mould, gases (VOCs) and odours.

PHI utilizes a broad-spectrum, high intensity UV light targeted on a hydrated quad-metallic catalyst surface. This target surface is covered with a proprietary quad-metallic and hydrophilic coating. The UV light reacts with the catalyst and moisture to produce an advanced oxidation plasma consisting of hydro-peroxides, super oxide ions and hydroxide ions.

These friendly oxidizers will revert back to oxygen and hydrogen once they’ve come in contact with and eliminated the pollutant. Find out more about Photohydroionisation here.

Controlled oxidation (giving up or losing of an electron) is an excellent way to destroy organics such as odours, viruses, moulds, bacteria and VOCs.

The PureAir Series emits ‘friendly’ oxidisers, meaning they revert to harmless oxygen, water and hydrogen.

Hydrogen peroxide has been used by the medical community for 170 years and is considered the safest oxidizer available (after oxygen). It is widely used today in toothpaste, mouthwash and household cleaners.

Hydroperoxides are known as Mother Nature’s natural cleaning agent. It is ionized hydrogen peroxides that make the air smell clean after a thunderstorm.

All Airius PureAir Series fans come with a 5 year Fan Replacement Warranty, as well as a 2 year PHI Cell Replacement Warranty. Simply return defective units to Airius, carriage paid and upon receipt Airius will dispatch a new unit by return carriage fully paid.

Light Emitting Diodes (LEDs) have been in common use for over half a century, mainly in electronic equipment, where they’re used as signals and indicators (standby lights, for example). It is only in recent years that LED light bulbs have been widely available. They are an energy efficient, longer lasting replacement for incandescent light bulbs. They emit the same brightness as traditional bulbs, using only a fraction of the power.

LED bulbs consume 90% less energy than traditional light bulbs. They also last 10-20 times longer. Over the lifetime of a typical LED light bulb, households could save a significant amount of money from reduced energy bills. Unlike energy saving CFLs, LED light bulbs can also be recycled.

Typically, LED lights have an average rated light of anywhere from 15,000-20,000 hours, compared to just 1,000 for traditional bulbs. Airius LED Lights however have a lifespan of up to 100,000 hours or more.

Lumens (lm) are a measure of the amount of visible light that a lamp emits. It is used to determine the brightness of a bulb (unlike a bulb’s wattage, which has no direct relation to its brightness).

Colour temperature refers to the type of white light that a bulb emits. ‘Warm’ white bulbs emit a softer, yellower light, while ‘cool’ white bulbs give off a bluer, more intense light. Colour temperature is measured in Kelvins (K), and typically ranges from 2000K-6500K. The lower the Kelvins, the warmer the light that a bulb emits. Typically, a warm white bulb for the home would be one with a colour temperature between 2700K-3000K, while a cool white bulb would be anywhere above 4000K. ‘Daylight’ bulbs are the coolest available, with a colour temperature around 6500K-7000K, and mimic the type of light the sun gives off during the day.

LED lights are green technology as they require a small amount of electricity compared to traditional lights to give out the same amount of light. LED lights also do not use the harmful chemicals that their CFL counterparts use.

A commercial electrician can design electrical wiring and system and work from electrical blueprints to ensure they are safe and compliant to support the needs of a commercial building, business and its electrical systems. They can also maintain, adapt, test and repair electrical wiring and circuits that control power for lighting, heating and cooling units, kitchen systems, refrigeration units and so on.

We carry out electrical contracting work for domestic, commercial and industrial customers.

This can range from householders, landlords, shops, letting/estate agents, housing associations, as well as high street stores including commercial and industrial companies nationwide.

We carry out all electrical system installation, maintenance, inspection and testing work. This can range from the installation of extra sockets and lights to rewires and new builds. We undertake small jobs as well as large contract work

– we have electricians and a pricing structure to suit all electrical work.

We can also provide a maintenance service for your property. Our inspection and testing service includes fixed wiring testing of the electrics within properties and appliances can be inspected and tested through our PAT Testing service.

If you have a question which was not answered here you can contact us at info@airius.co.uk or by phone on +44 (0) 1202 554200 .

We carry out all electrical system installation, maintenance, inspection and testing work. This can range from the installation of extra sockets and lights to rewires and new builds. We undertake small jobs as well as large contract work

– we have electricians and a pricing structure to suit all electrical work.

We can also provide a maintenance service for your property. Our inspection and testing service includes fixed wiring testing of the electrics within properties and appliances can be inspected and tested through our PAT Testing service.

Yes. In addition to our normal hours of 9-5 Monday to Friday, we are also able to provide

flexible installation times 24 hours a day, 7 days a week to fit in around you and your timetable.