No products in the cart.

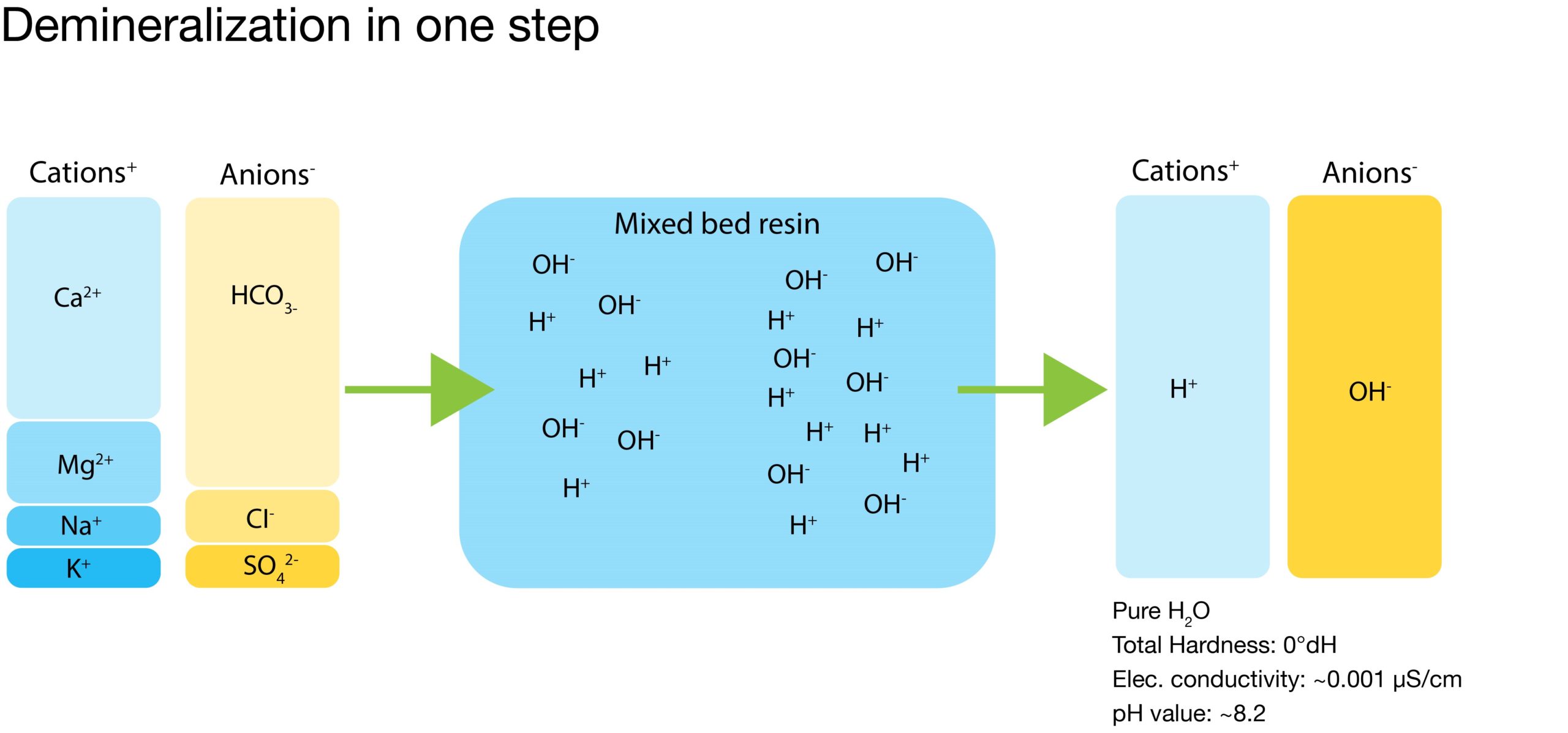

Top quality Resin for heating systems:

It is not possible to tell the quality of a mixed bed resin from its appearance. Magnetic GmbH examines every delivery in their laboratory to determine whether the resin meets the standards that is promised. The resin is only dispatched when this quality level can be guaranteed.

The quality of the resin determines has a direct impact on the quality of the heating water. It is particularly important not to compromise on the resin.

Magnetic GmbH Premium mixed bed resin effective and durable.